Dairymaster’s new RoboSpray System is “udderly” fantastic!

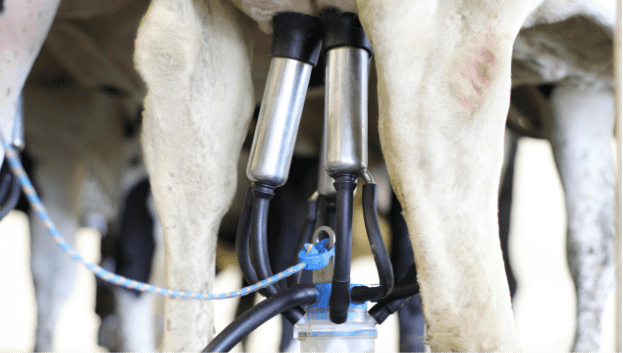

RoboSpray is a robotic arm that gives a more precise and consistent spray pattern, closer to the udder, thus ensuring a better coverage of all teats and a more effective use of the disinfectant. The RoboSpray system includes machine vision technology to correctly position the spray head and monitor its progress.

Read more